Welcome To Naik Oven Manufacturing Co.

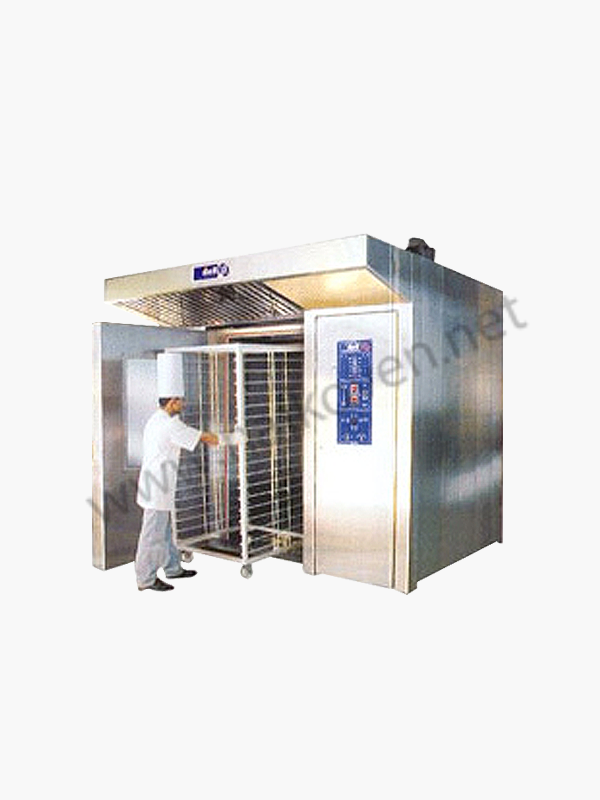

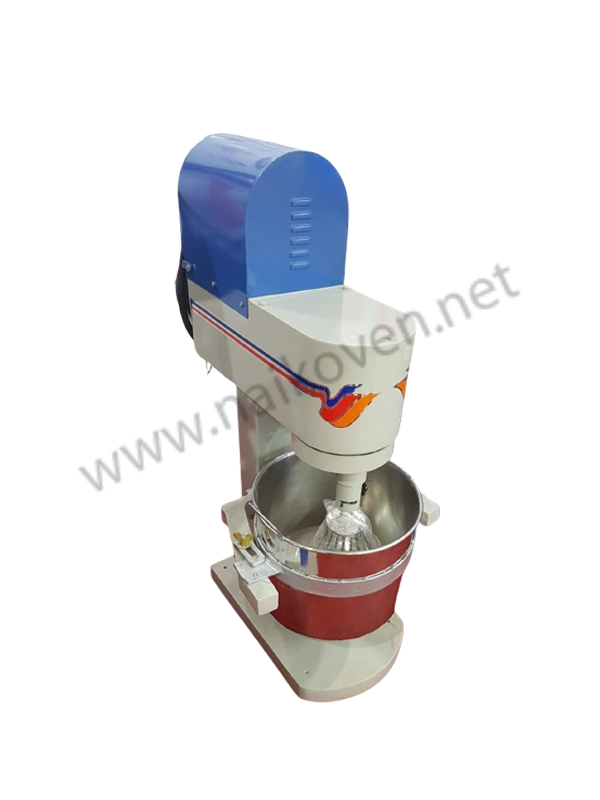

We are an ISO certified company, engaged in manufacturing, supply and export of best quality rotary rack ovens and bakery machinery. Precision engineered using cutting edge technology, our range reflects the perfect blend of form and function.

Making the baking process fast, convenient & economical, our range has not just proved its significance & utility amidst domestic clients, but in addition, it has established a firm footing in different overseas markets including Nigeria, African countries and many more. Bharat Bakery, Bemisal Bakery, Kwality Bakers, Rajlaxmi Bakers etc are some name, which have expressed unwavering trust and positive response towards our products like double & single rack ovens, spiral dough kneader, planetary cake mixer, bread slicers etc.

We Offer Rotary Rack Ovens, Stainless Steel Rotary Rack Oven, Dough Sheeter, Bakery Rotary Rack Ovens, Gas Rotary Rack Ovens, Electric Rotary Rack Ovens, Diesel Rotary Rack Ovens, Dough Kneader, Cookies Rotary Rack Oven, Bakery Oven, Industrial Rotary Rack Oven, Bakery Oven Equipment, Single Rotary Rack Oven, Double Rotary Rack Oven, Deck Oven For Bakery, Mini Rotary Rack Oven, Small Rotary Rack Oven, Planetary Cake Mixer, Bread Slicer Machine, Spiral Mixer, Manufacturers, Suppliers, Provider, Fabricator, Exporters in Mumbai, in Navi Mumbai, in Thane, in India.

STUDY CONSTRUCTION

DURABLE & TOLERANT BODY

SAFE & HYGIENIC

ENERGY SAVING INSULATION

RESISTANT TO CORROSION AND TEMPERATURE VARIATIONS

PROOF TO RUGGED ENVIRONMENT

ENERGY SAVING INSULATION